Cask beer is a wonderful product full of a variety of tastes and aromas, a great testament to the skills of the brewer, but being an unpasteurised living product it needs the skills of the licensee to get it perfect for the drinker. Understanding how to handle cask beer is therefore vital to the success of your business.

The first and arguably most important rule is to keep everything clean, they say cleanliness is next to godliness but in the pub cleanliness is godliness. Beer lines, taps, pegs, dip sticks all should be spotless. Think of the cellar as your kitchen, if you spilt a pint of milk in the kitchen you would immediately clean it up… do the same in the cellar. Spilt beer can attract bacteria and wild yeasts, both can contaminate your beers.

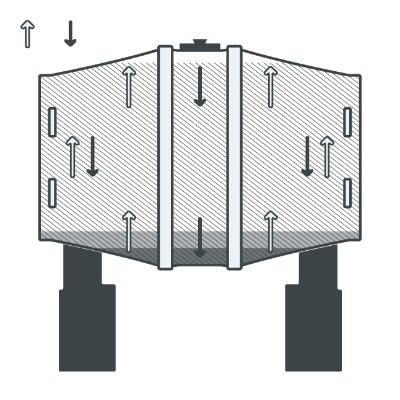

When the casks are delivered get them up onto the stillage, making sure they are flat and secure.

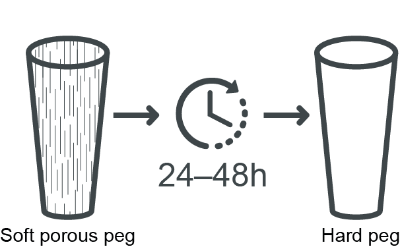

Once they have reached cellar temperature our advice would be to vent them all with a soft peg, so that they start to drop bright. Some licensees think the beer will go off if vented too early but the beer only starts to deteriorate when you start to sell it as this draws air into the cask.

Once all the beer has finished venting, this is easy to see as it stops bubbling from the soft peg, (normally about 24hrs) seal them back up with a hard peg and leave them to condition.

What’s happening in the cask is all of the flavours are maturing and rounding off, the yeast, that is now at the bottom, is fermenting and producing CO2 and giving the beer “life”.

How long should you condition?

Different brewers have their own guides but it’s normally 3 – 5 days. Some strong beers can be conditioned longer and in our experience, a pub that sells amazing beer normally conditions longer.

When do you tap the beer?

We recommend you tap the beer with a clean fresh tap 24hrs before you want to use it. If you tap and vent at the same time you run the risk of the yeast settling on the back of the tap making the first pints off cloudy. Also once a tap is in the cask it is a potential contamination risk, as wild yeast and bacteria in the environment can get on the tap and may get into the beer turning it off before you even start to sell it!

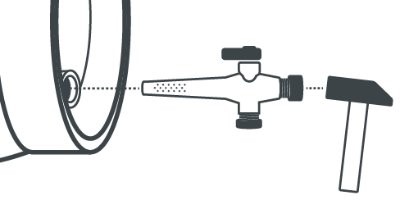

When you’re ready to sell the beer, sample it first just to make sure it’s okay before you connect the beer line. Then connect the line, don’t forget the hop seed filter, this stops hop seeds getting into the beer pump and also helps makes a seal at the tap so you don’t get beer leaking onto the floor. Loosen the hard peg, turn on the tap and off you go.

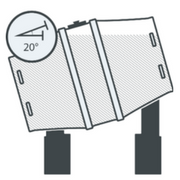

At the end of a session tilt the cask 3-4 inches at the back to make sure you get all of the good beer out of the cask. If you have automatic tilters the job is done for you. Don’t forget to seal the hard peg back in between sessions to minimise the risk of anything getting into the beer.

Once on sale you ideally want to be selling the whole cask in 3-4 days as being a living product it will deteriorate over time.

Once the cask is finished you should have ½ – 1 pint of yeast sludge at the bottom. Don’t forget to knock the hard peg in the shive, remove the tap for cleaning and seal the keystone with a cork or plastic bung. This keeps the cask wet making it easier for the brewer to clean it.

If you’ve gone through the process and done everything correctly, when the drinker holds the pint up and proclaims that “this is a fine ale” you can take pride in a job well done!

For more information on stillaging, venting, conditioning and all other aspects of best cellar practice, just ask our friends at CellarCraft.